EXCLUSIVE FORUM FOR MACHINE DISMANTLERS AND REPAIR PEOPLE > Merrillville

> Self Propelled

> Air Brakes

> Under 150 PSI

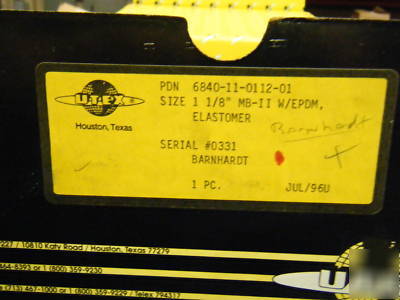

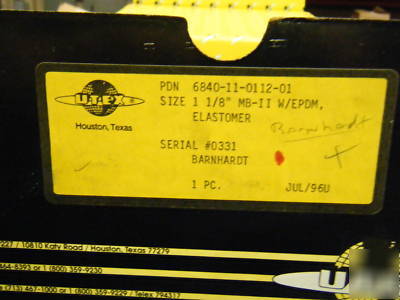

> Utex mechanical seal size 1-1/8" mbii w/epdm, elastomer

Utex mechanical seal size 1-1/8" mbii w/epdm, elastomer

THE UTEX SEAL THAT KEEPS YOU PUMPING LONGER

The unique MB-II can be operated as either a double or tandem seal, both of which are hydraulically balanced, making it one of the most versatile seals available. It is designed and built to reduce and/or eliminate fugitive emissions and to increase mean time between planned REPAIRS (MTBR).

The dual stationary bellows assembly self adjusts for misalignment and reduces the potential for harmonic vibration. The extremely low mass of the face and bellows assembly improves face tracking characteristics during operation.

The buffer fluid is sealed on the O.D. of the outboard bellows. This prevents heat related problems resulting from air entrapment and dead fluid zones. Also, higher buffer fluid pressures are attainable. A tangential flow pumping ring produces a high performance flow of buffer fluid for efficient cooling and helps prevent abrasives from settling in the seal cavity.

The MB-II fits ANSI pumps without modification. Temperature range is from -75 F to +400 F (-60 C to +204 C) depending on the o-ring material chosen. Maximum pressure differential is 300 psi (20 bar) across either bellows, with speeds up to 4500 fpm (23 m/s).

Hastelloy C-276 bellows core. 316 SS standard end fittings, Hastelloy C available.

Standard - 316 SS metal parts.

Available - Hastelloy C and Alloy.

Standard - CNFJ-B grade carbon.

Available - EPDM, Neoprene, Nitrile, Chemtex, Aflas, Chemraz, Kalrez, PTFE, and encapsulated Viton.

-75 F to +400 F (-60 C to +204 C) depending on o-ring material chosen.

300 psi (20 bar) across either bellows

Double Mode - 275 psi (19 bar)

Tandem Mode - 300 psi (20 bar)

Double Mode - 300 psi (20 bar)

Tandem Mode - 275 psi (19 bar)

INLET/OUTLET CONNECTION SIZES:

" N.P.T. for seal sizes 1" thru 1 "

3/8" N.P.T. for seal sizes 1 5/8" thru 2 "

1. Unitized construction of welded bellows assembly.

1. Fewer parts, even face loading, uniform linear spring action.

2. Fretting corrosion is eliminated since the O-rings are not required to flex or roll to maintain sealing; the seals cannot become immobilized if the O-rings swell or char when exposed to aggressive solvent or heat; Viton encapsulated O-rings can be used throughout the seal.

3. Bellow's core is Hastalloy C-276 as standard.

3. Improved stress corrosion resistance, wider range of chemical resistance.

4. Provides positive flow of buffer/barrier fluid, better heat dissipation compared to thermal convection.

5. The entire outboard bellows seal is inside the outboard seal gland cavity, with the fluid on the seal O.D.

5. More stability and reliability, eliminates the following problems associated with i.d. pressurized outboard seals: air entrapment that can cause dry running; "dead zones" of uncirculated fluid that can overheat and cause loss of lubrication abrasive wear due to particles being thrown into seal faces by centrifugal force; low pressure capabilities (typically less than 150 psi).

6. Stationary bellows design on both inboard and outboard seals (currently a UTEX exclusive feature).

6. Self-aligning, lower emissions in ppm, adjusts for stuffing box misalignment without bellows fatigue, requires no vibration dampeners which can cause face hang-up or fretting, eliminates viscous drag on the bellows, can be used in more viscous products.

7. Inboard bellows seal is double balanced.

7. Operates in either a dual pressurized or non=pressurized seal.