EXCLUSIVE FORUM FOR MACHINE DISMANTLERS AND REPAIR PEOPLE > Gary Indiana

> Agricultural and Construiction

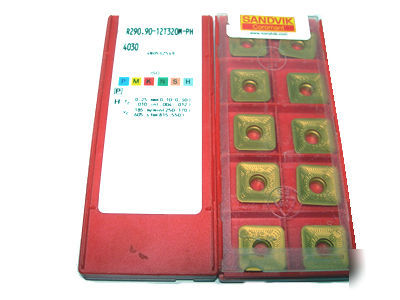

> Sandvik carbide inserts R290.90-12T320M-ph 4030 10PCS

Sandvik carbide inserts R290.90-12T320M-ph 4030 10PCS

- Reinforced cuting edge for heavy maching

Sandvik grade 4030 is a multi-layer coated grade dedicated for all types of milling of unalloyed and low alloy steels in both wet and dry operations where workpiece tolerances and surface finish require the use of cutting fluid. Reduction of cutting data for milling in wet conditions is not required due to the superior edge line security, making GC4030 an extremely easy to use CoroKey grade. Production tests show improved production economy due to long predictable tool life, giving lower costs per insert, fewer indexes, less adjustment and the possibility of unmanned operations. GC4030 is a well defined steel milling grade with its optimum performance covering a large proportion of the material group - unalloyed and low alloy steel with hardness up to HB300. Due to the superb machining performance in both wet and dry conditions, GC4030 is the first choice grade for steel milling. Long tool life in combination with predictable wear behavior also makes GC4030 a reliable choice for operations with reduced manning. The advanced processing technique, with its wear resistant multi-layer coating (TiCN+Al2O3+TiN) provides excellent adhesion between each layer and toughness of the substrate. This has resulted in the main benefit of GC4030 inserts - a long, reliable tool life. GC4030 also has very good edge line security - particularly in wet milling. Flaking and thermal cracks along the insert edges is substantially reduced when using the same cutting speed as recommended for inserts of a similar composition. The result is a considerable increase in tool life.