EXCLUSIVE FORUM FOR MACHINE DISMANTLERS AND REPAIR PEOPLE > Dolton IL

> Light Machinery

> Axels

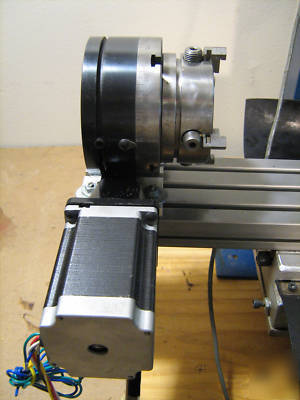

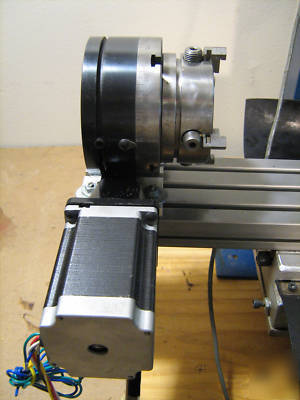

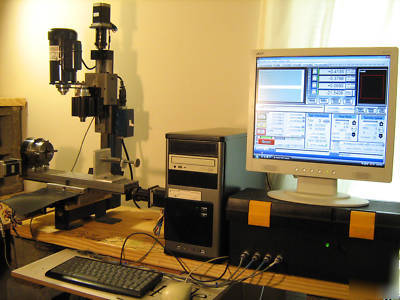

> Taig cnc mill 4-axis

Taig cnc mill 4-axis

*Advanced Bilevel Chopper Drive technology coupled with new 277 oz-in. stepper motors providing rapid traverse speeds of 30 inches/minute with High Motor Torque.

*Step resolution of 0.000125 inches.

*Precision Engineered Steel and Aluminum structural design.

*STEEL CUTTING;capability with tests showing a single pass 1/8" depth slot cut in mild steel with a 1/8" end mill -Try This on other desktop mills!

*SHOP AND COMPARE the TAIG MicroMill to any other machine on the market today and decide which is the FASTEST, MOST PRECISION, POWERFUL, RUGGED, MOST CAPABLE and ECONOMICAL desktop machine on the market today!

Maximum Travel Speed: 30 in/min.

HARDENED ER16 Spindle in Mill Head

Max cutter shank : 3/8 (with 3/8 ER16 collet)

Maximum Travel: X = 9.5", Y = 5.5", Z = 6.0"

Table dimensions 3 1/2 x 15 1/2 inches

Maximum Z distance to table : 8.0"

Mechanical Resolution: 0.0005 in.

Electrical Resolution: 0.00013 in.

Spindle Speeds: 1100-10000 RPM.

Rigid square tubular steel base and column construction.

X Axis - Hard Anodized cross slide table with 45 deg. dovetail.

Y Axis - Precisionly ground prismatic 90 deg. steel rail ways.

Total Dimensions with motors 21" x 20" x 24".

Total Weight 85 lbs. (of mill with out steppers)

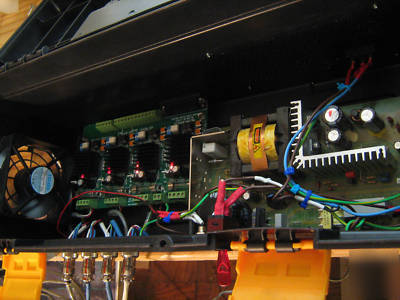

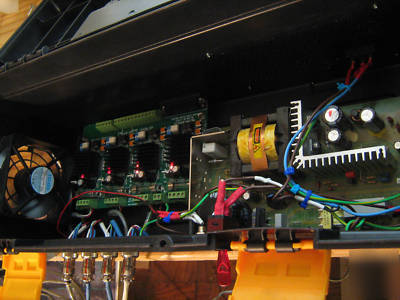

* Made with Top Surface Mount Technology

* Two phase bipolar (PWM Technology) this board doesn't need any external resistor for current motor adjustment.

* Resolution (Full step, 1/2 step, 1/4 step, 1/8 step) selectable via dip switch for each axis, also, you can get a resolution of 1600 steps per 360 revolution with a conventional 200 steps motor, Imagine the fine movement that you will get!

* 2.5A motor current capacity per phase, in every axis

* Individual axis enable/disable, via optocoupler input terminal (can be used as limit switch)

* Full Adjustable stepper motor current via potentiometer on board

* DB25 MALE connector on board for PC parallel port

* All inputs signals are optocoupled for PC parallel port protection

* Full access to all unused DB25 pins connector via terminal block, easy connection for prototyping work

* 24VDC @ 2-to-6 amp power supply required, 12VDC as minimum, 32VCD as maximum

* Individual heat sink per axis

* 4 Wire, 6 Wire and 8 Wire (NEMA 17, NEMA 23, NEMA 34) Bipolar or Unipolar stepper motors can be used with 3 axis drive

* Fuse integrated for electrical protection

*more info on the control board can be found at- http:// /4axisdriver.html

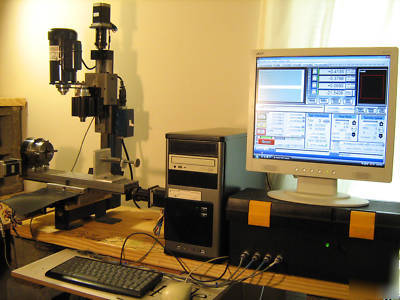

I put this computer together specifically to run the this mill. It far exceeds the system requirements to run Mach3 and the mill. However I found it useful to have a computer that is power full enough to edit models and recalculate tool paths with out transferring from data between computers.

Software- Vista and and Full copy of Mach3 the set up is all ready to go!!!!! Just plugin your G-code and you are set to start milling!!!

-2 printer ports/ one on the mother board, and one card

-AMD Phenom Quad core 9550 processor

-Process Type: AMD Phenom X4 Quad Core Processor 9550

-The computer also comes with a compact keyboard, mouse and 17in LCD monitor.

2- chucks that fit the 4th axis table

52 assorted End Mills and Drill bits