EXCLUSIVE FORUM FOR MACHINE DISMANTLERS AND REPAIR PEOPLE > Dolton IL

> Agricultural and Construiction

> Food

> Duraflex flexible molding casing radius 12 foot

Duraflex flexible molding casing radius 12 foot

Can accommodate virtually any radius which is 3 times a profile width or greater, Seamless construction without lamination defects!

Moisture proof. Insect proof. Can withstand extreme heat and cold temperatures without warping, cracking or deteriorating

Ease of installation using standard woodworking equipment - cut, sand, shape and finish like any standard wood product!

THIS LISTING WILL NOT END .. IT WILL AUTOMATICALLY RELIST AT THE END ... PLEASE DO NOT WAIT

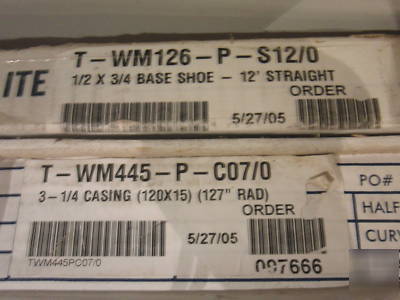

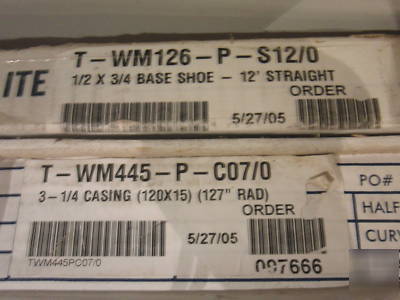

The box is the actual box. The other pictures are samples from the manufacturer's website. The box shows some wear from storage.

I also have duraflex shoe molding.. 1 roll of 12 foot -1/2 inch by 3/4 inch straight molding

The original economic alternative to curved wood applications where wood mouldings simply won't bend. DuraFlex mouldings, developed by ResinArt in 1967, are consistently asked for by discriminating architects, builders, contractors, remodelors, designers, and homeowners.

Welcome to ResinArt Specialty Applications Include

* The appearance of real wood

* Ease of installation using standard woodworking equipment - cut, sand, shape and finish like wood

* Seamless construction without lamination defects

* Can accommodate VIRTUALLY ANY RADIUS WHICH IS 3 TIMES A PROFILE WIDTH OR GREATER

* Moisture proof. Insect proof. Can withstand extreme heat and cold temperatures without warping, cracking or deteriorating

Duraflex - the original flexible moulding

If you have a question we don't address,

please call or eMail us today:

CHECK OUT OUR NEW RADIUS CALCULATOR.

The following are procedures and instructions for the installations of DuraFlex and XtraFlex Mouldings.

For best results, the use of polyurethane construction adhesive in addition to pneumatic pin nailing is recommended. Use of tape or clamps may be helpful in securing material in position while adhesives bond. Nails should be kept to a minimum and 3/8" from any edge.

Material can be cut, shaped and sanded using standard woodworking equipment. Note that the wood grain on Stain grade material is only on the surface and will be eliminated if sanded.

The use of water based stain such as Minwax works well. Apply with brush or rag and wipe off. Additional coats may be applied if necessary to match wood. Be sure to allow first coat to dry completely before applying more stain. Finish with clear coat after staining.

Primer coats are not recommended. Use water based Acrylic Latex Paint. When using Alkyd Enamels an exterior primer such as Kilz is required. When using Alkyd Enamels additional drying time may be necessary. Never paint before installation. The material is flexible and the paint may crack during installation.

Installation Tips - Half Round and Arcs

1. Check thickness of product to thickness of matching wood where DuraFlex Moulding and the wood moulding will meet. It may be necessary to shim or plane off either product to have material properly line-up.

2. Align radium product to window.

3. Support DuraFlex Moulding by tacking in place to see proper alignment.

4. Nail first at top of arch and work toward ends.

Installation Tips - Crown Mouldings

1. Check thickness of DuraFlex Moulding to thickness of any other product being butted against it. May be necessary to shim or plane-off either product to have material properly line-up.

2. Support DuraFlex Moulding in position to check proper fit.

3. Pre-drill nail and screw holes.

4. Fasten nails and screws into cleating on wall.

5. Use drywall screws for large crowns along with adhesive.

6. All crowns are made to a specified radius. Do not compress or stretch material - cracking may occur.

Installation Using GEL Super GluesInstallation Using GEL Super Glues

Apply bead of adhesive where moulding bonds to wallboard and another bead where moulding bonds to jamb or window (see picture A). Put into position and hold firmly until adhesive sets (approx. 2 minutes). Increase the cure rate to 5 - 10 seconds by spraying accelerator at edge between moulding and wallboard (see picture B).

By using the GEL Super Glues nailing and nail holes are eliminated.

For arched door entries and other arched openings, we will need two measurements; WIDTH and RISE. The width is the widest distance at the base of the arch and the rise is the largest distance between the base and the top of the arch.

Rise: (rounded to the nearest inch)

Width: (rounded to the nearest inch)

http://east.resinart.com/index.php?option=com_wrapper&view=wrapper&Itemid=149